•Application:

API 16C Choke and Kill Hose is an important part in choke and kill system, which is an integral part of surface and subsea blowout prevention equipment.

1. This hose allows to pump fluid to the well when normal circulation through the drill string couldn't be performed.

2. Additionally the choke hose and manifold provide a means of applying back pressure on the formation while circulating out formation fluid influx into well bore following a kick.

3. To pump sour fluid;

•Standard: API Spec 16C.

•Hose structure:

Inner Tube: Particular polymer engineering plastic as inner sealing tube.

Inner rubber Layer: HNBR based inner sealing elastomer, which is suitable to H2S, oil resistance, corrosion resistance, high temperature resistance, gas permeation resistance

Breaker Layer and external protection layers: High tension textile fabric

Major Reinforcement for withstanding pressure: High Strength Steel Cable

Fire shield layer: Glass fiber cloth

Cover: Neoprene based rubber based cover, anti-flaming, wear resistance, oil resistance, ozone & ageing resistance, UV resistance, which is designed for marine environment.

•Hose has passed verification test specified in Clause B12, API 16C.

•Heat trace cable can be assembled by functional requirement.

•Different option of external protection layer are available as request or by our recommendation according to specific operation condition, for example, stainless steel armor outer wrap, embedded stainless steel wire in cover, or polyethylene spiral guard, etc.

•Metal connector: meet NACE MR0175 / ISO 15156

•Working temperature: Class II, -25℃ to +100℃ (-13℉ to +212℉)

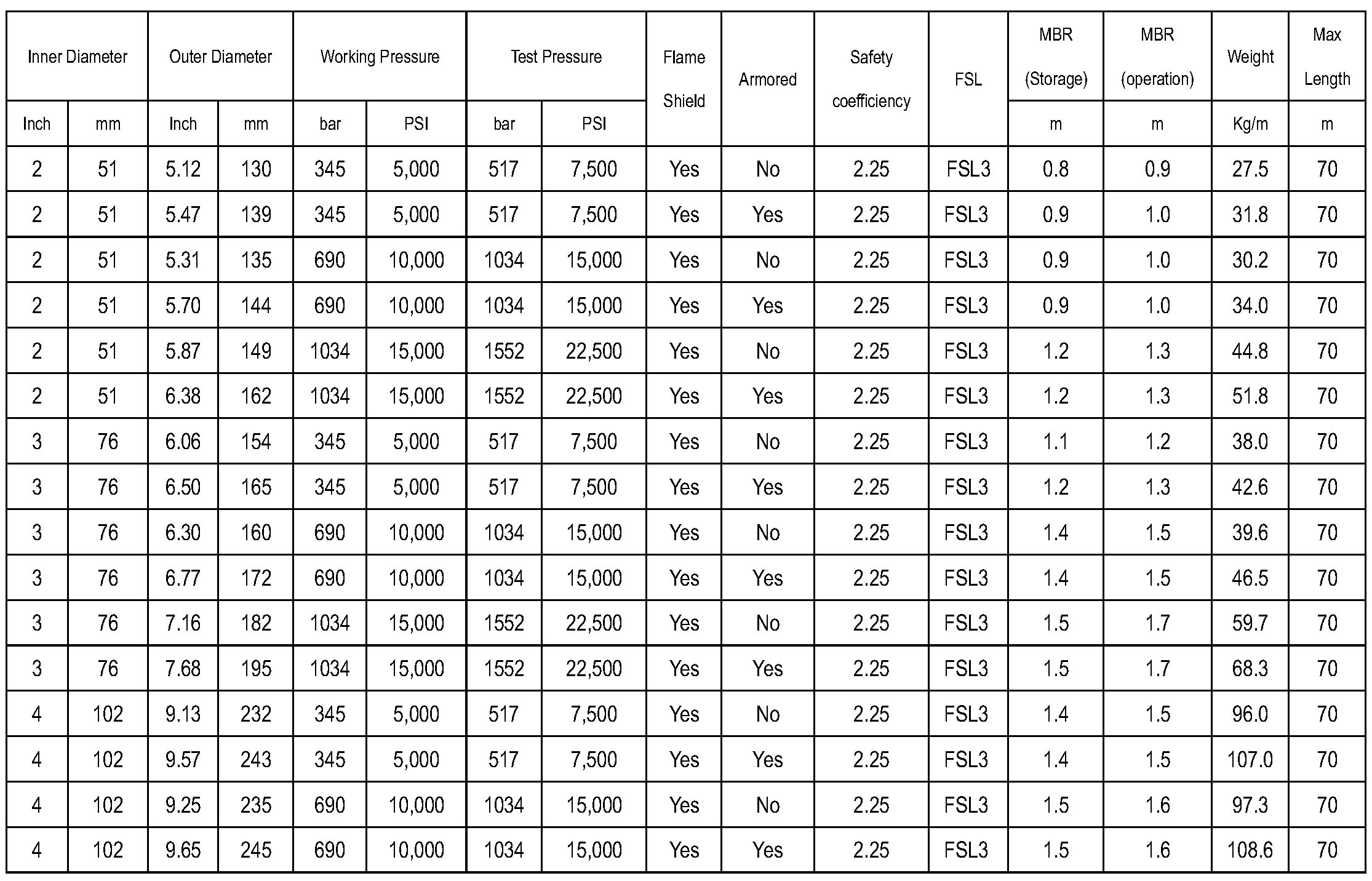

•Flexibility specification level: FSL3

•Maximum continuous length: 70 meters

•Length tolerance: Length up to 6.4m, with tolerance 64mm; Length longer than ±6.4m, with tolerance ±1%;

•Measurement basis of Minimum Bending Radius (MBR) is center line of each hose.