•Application:

It is used in well cementing system of offshore and land drilling rig, flexible connection between cementing pump and top drive for delivery of high-pressure cement.

•••Standard: API Spec 7K / ISO 6807

•Hose Structure:

Tube: CR rubber based liner sealing layer, abrasive resistance, alky-acid resistance, high temperature resistance.

Breaker Layer and external protection layer: High tension textile fabric.

Major Reinforcement for withstanding pressure: High strength steel cable.

Cover: Neoprene based cover rubber, anti-flaming, wear resistance, oil resistance, ozone & ageing resistance, UV resistance, which is applicable for marine environment.

•Fire proof grade:

Regular supplied hoses meet fire proof grade SR6A, 704℃ (1300℉) X 5 minutes.

Fire-rated hoses supplied as per request with extra fiberglass outer layers for fire shield, meet fire proof grade SR6B, 704℃ (1300℉) X 30 minutes.

•Embedded electric heat trace cable is available as request for low temperature operating condition.

•Different options of external protection layer are available as request or by our recommendation according to specific operation conditions, for example, stainless steel armor outer wrap, embedded stainless steel wire in cover, or polyethylene spiral guard, etc.

•Working temperature range: Class II, -25℃ to +100℃ (-13℉ to +212℉)

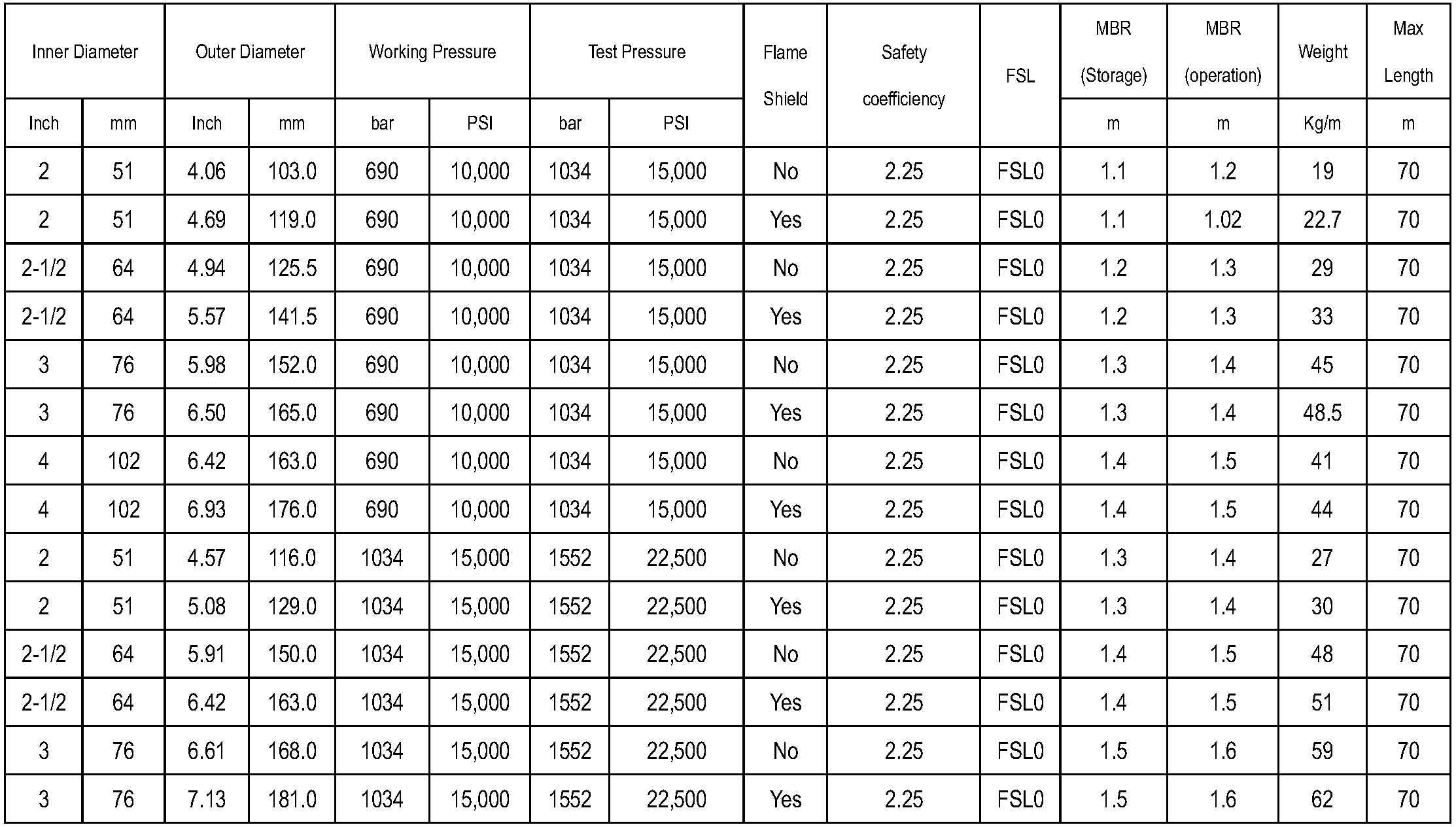

•Flexibility specification level: FSL0

•Maximum continuous length: 70 meters

•Length tolerance: Length up to 6.4m, with tolerance ±64mm; Length longer than 6.4m with tolerance ±1%

•Measurement basis of Minimum Bending Radius (MBR) is center line of each hose.