During Drilling

operation, major wear and tear wear often take place between drill pipes and

casings. Wear Sub is used to avoid such wear between drill pipes and casings.

With features, such as compact structure adn easy operation, wear sub can

prolong the service life of drill pipe and casing and reduce the vibration and

trembling of drilling tools. It can also limit the contact friction between

metals.

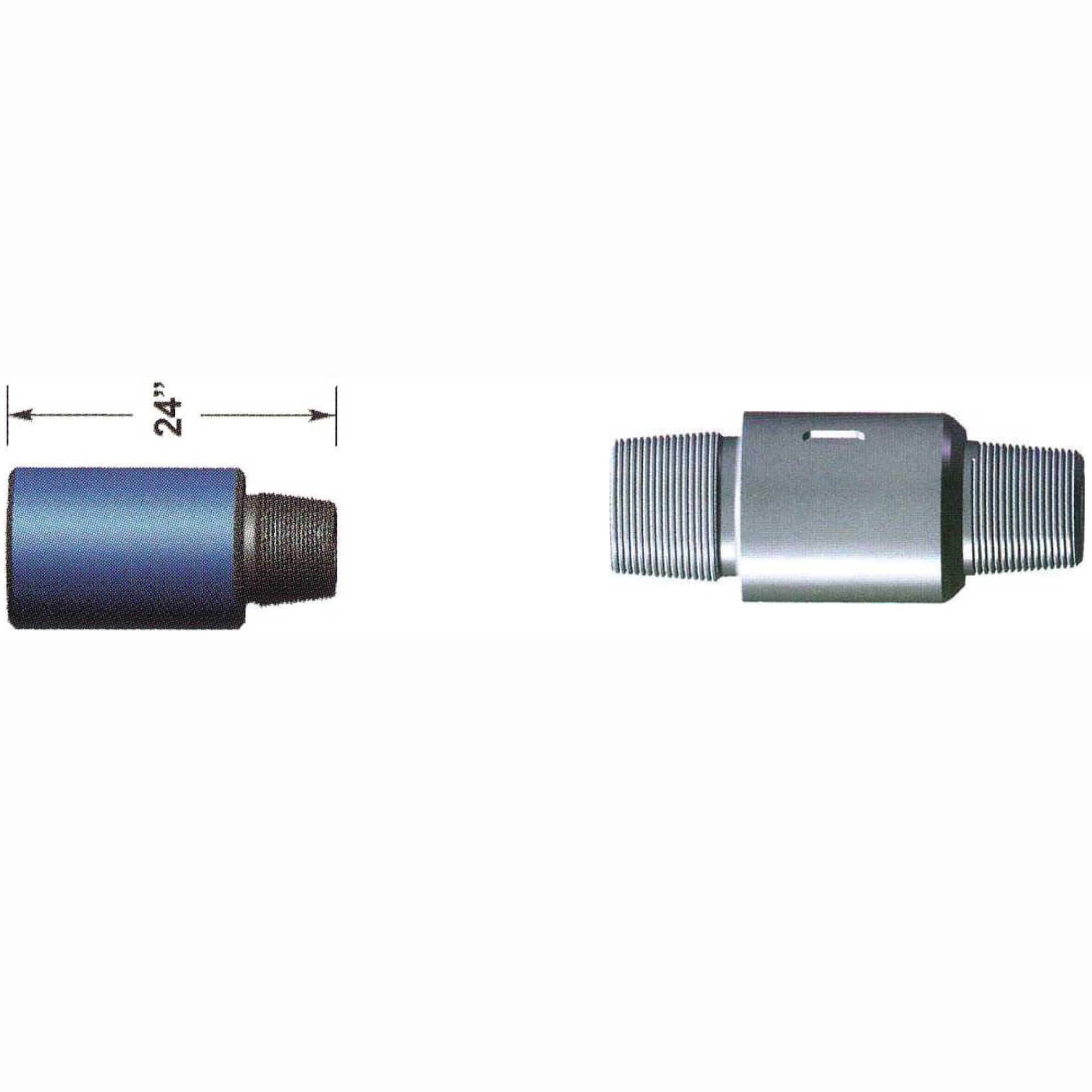

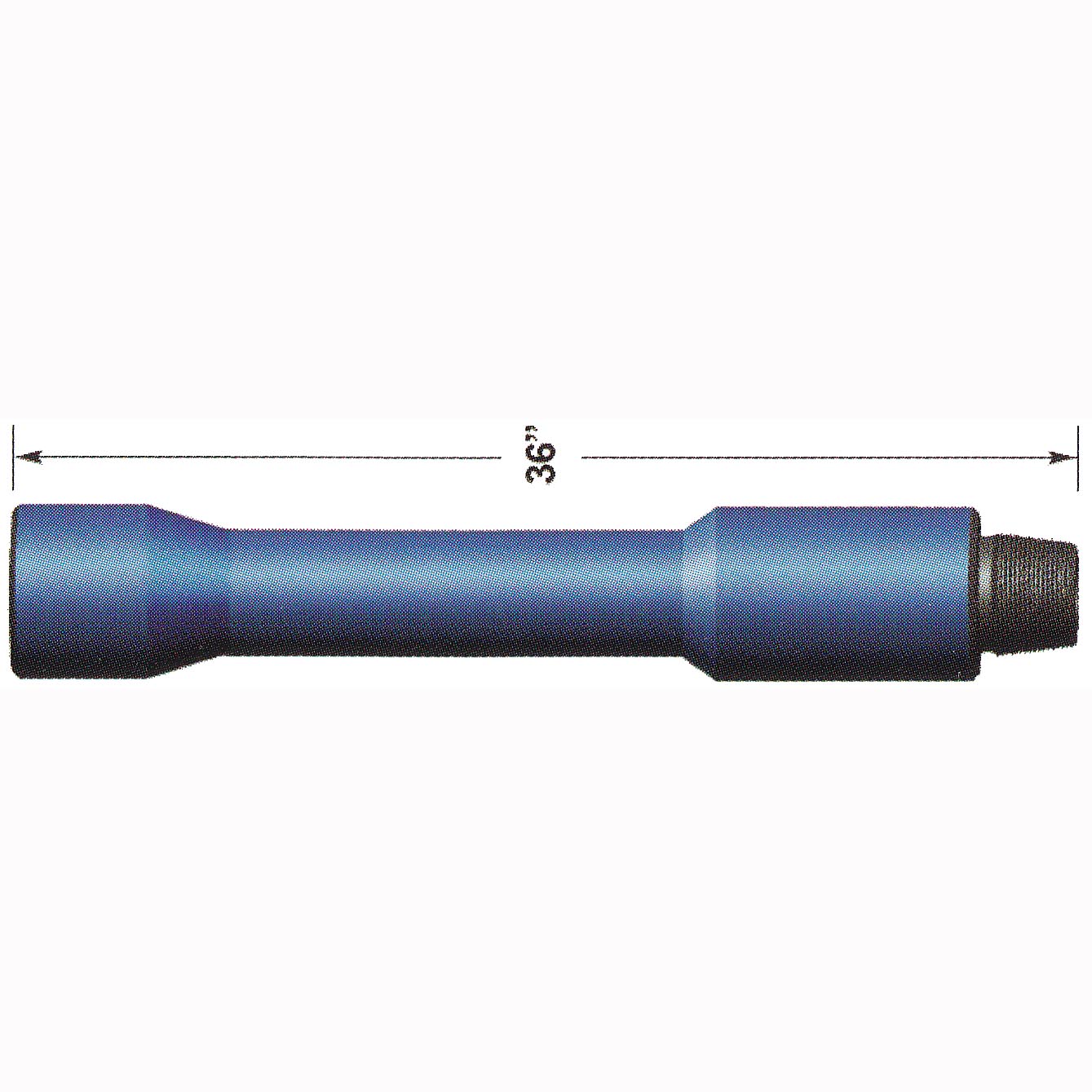

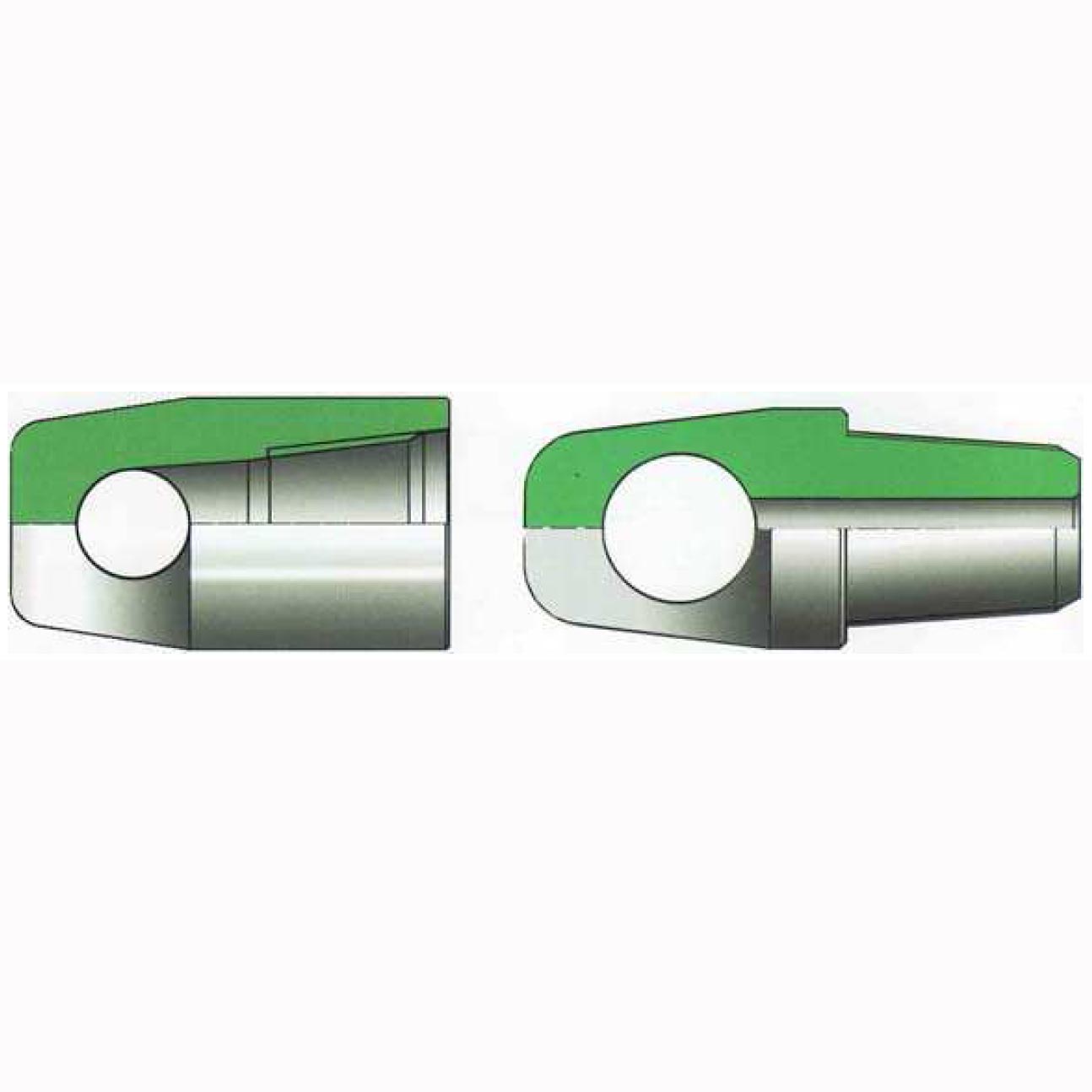

The wear sub consists

of a highly wear rubber sleeve, a metal stiffening liner and a sub body. The

rubber sleeve is installed in the middle of sub body and some clearance is

given to allow sleeve to rotate freely. The rubber sleeves are made of rubber

mixtures with good wear resistance.

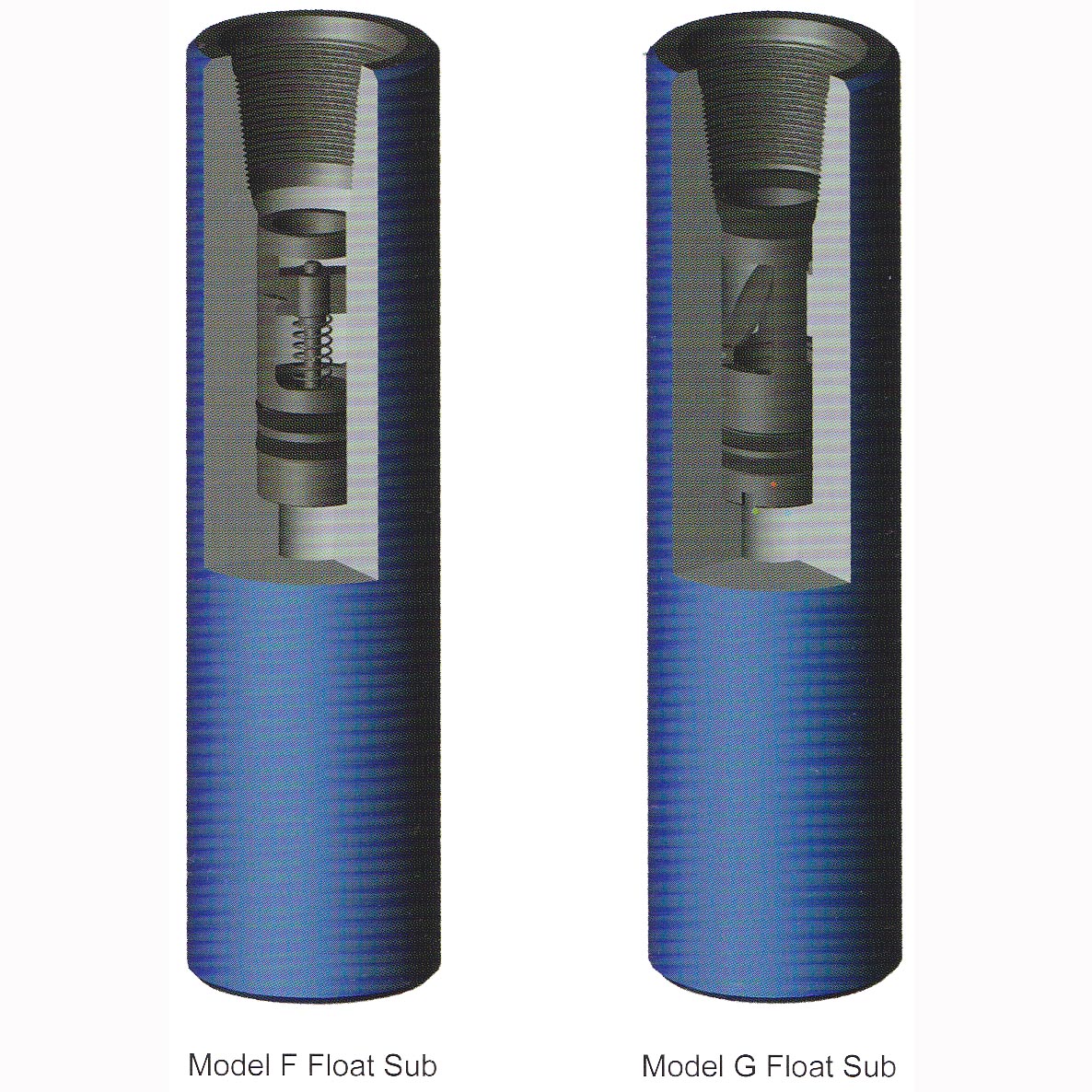

During drilling

operation, the rubber sleeve and sub body can make a relative rotation. The

rubber sleeve OD is larger than drill pipe tool joint OD, therefore the tool

joint and drill pipes cannot come in contact with casing. The rubber sleeve on

wear sub will first contact casing. When friction between rubber sleeve and

casing takes place, wearing can be reduced due to the rubber sleeve wear

resistance and softness. Usage of tool joints of drill pipes and drill string

tools will also be reduced.

Technical Parameter

|

Spec |

Body OD mm |

Sub OD mm |

ID mm |

Connection |

|

7" Casing |

121 |

143 |

38.1 |

3-1/2IF |

|

9-5/8" Casing |

168 |

190 |

71.4 |

4-1/2IF |

|

178 |

197 |

71.4 |

5-1/2IF |

|

|

10-3/4" Casing |

180 |

225 |

71.4 |

4-1/2IF |

|

5-1/2IF |

||||

|

13-3/8" Casing |

203 |

285 |

71.4 |

5-1/2IF |