•Application:

Delayed coking unit is an advanced processing unit in oil refinery industry. Delayed coking process is an important technology for deep processing of heavy oil and residual oil. Hydro decoking hose plays an important role in delayed coking unit by delivering high pressure water to coke block cutting equipment in coke tower.

•Standard: API Spec 7K.

•Hose structure:

Internal Tube: Nitrile rubber based liner, wear resistant, acid & alkali resistant, high temperature resistant and ageing resistant.

Breaker Layer and external protection layers: High tension textile fabric

Major Reinforcement for withstanding pressure: High Strength Steel Cable

Cover: Neoprene based rubber liner elastomer, anti-flaming, wear resistance, oil resistance, ozone & ageing resistance, UV resistance, which is designed for critical marine environment.

•Electric heat trace cable available by functional requirement.

•Different option of external protection layer are available as request or by our recommendation according to specific operation condition, for example, stainless steel armor outer wrap, embedded stainless steel wire in cover, or polyethylene spiral guard, etc.

•Working temperature: Class II, -25℃ to +100℃ (-13℉ to +212℉)

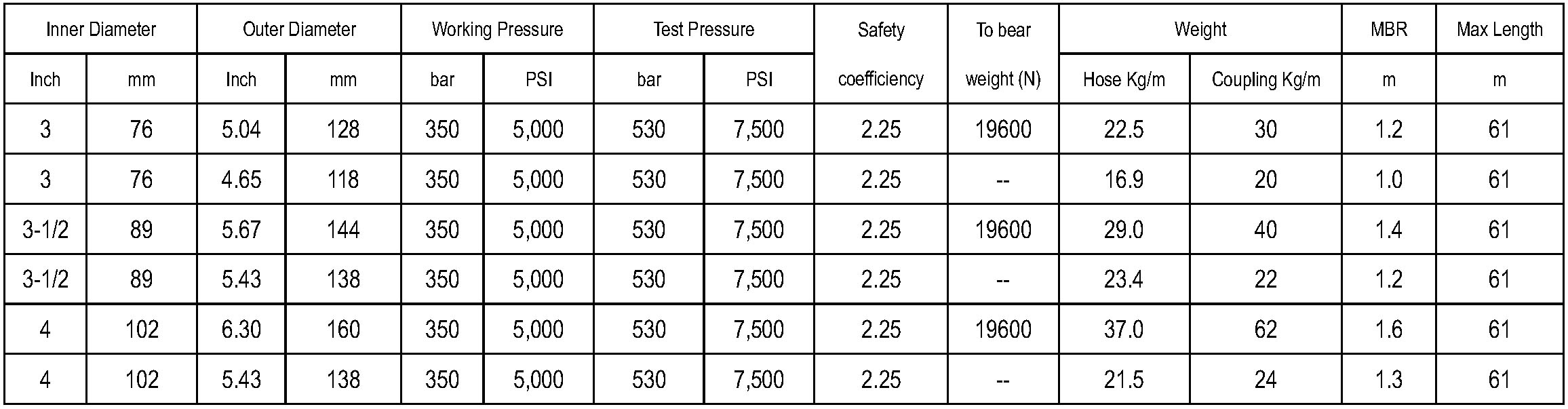

•Maximum continuous length: 70 meters

•Length tolerance: Length up to 6.4m, with tolerance 64mm; Length longer than ±6.4m, with tolerance ±1%;

•Measurement basis of Minimum Bending Radius (MBR) is center line of each hose.